The global polymerization initiator market size reached nearly USD 3.17 billion in 2024. The market is projected to grow at a CAGR of 4.4% between 2025 and 2034 to reach a value of around USD 4.68 billion by 2034. This growth highlights the increasing demand for polymerization initiators, which are essential in producing various polymers for industries like packaging, automotive, and construction. This blog delves into the market’s dynamics, exploring its size, share, trends, segmentation, and challenges, alongside recent developments and a competitive landscape.

Market Overview

Polymerization initiators play a pivotal role in producing high-performance polymers. These chemical agents trigger the polymerization process by generating reactive species such as free radicals, anions, or cations. The resulting polymers find applications in diverse sectors, including consumer goods, automotive, electronics, and infrastructure. With increasing industrialization, urbanization, and demand for lightweight, durable materials, the market for polymerization initiators continues to expand.

Market Size

The global polymerization initiator market size was valued at USD 3.17 billion in 2024. Fueled by the growing need for advanced polymers, the market is forecasted to grow steadily at a CAGR of 4.4% during 2025-2034. By 2034, the market is anticipated to reach approximately USD 4.68 billion. This growth is underpinned by advancements in polymer technology, rising demand for eco-friendly alternatives, and a robust expansion of end-use industries globally.

Market Share

Among the key contributors to the polymerization initiator market, Asia-Pacific dominates with the highest market share due to rapid industrialization and the presence of a thriving manufacturing sector. North America and Europe follow, with significant contributions driven by technological innovations and a focus on sustainable polymer production. Within the product segment, free radical initiators account for a major share, given their widespread use in producing polyethylene and polypropylene.

Market Trends

Sustainability Initiatives: The growing emphasis on environmental sustainability is driving the development of eco-friendly polymerization initiators. Manufacturers are investing in green technologies to minimize environmental impact.

Technological Innovations: Advances in initiator chemistry, such as improved efficiency and reduced toxicity, are reshaping the market. Innovations in microencapsulation techniques enhance initiator performance and stability.

Rising Demand in Emerging Economies: Rapid industrial growth in countries like India and China is fueling the demand for polymerization initiators in packaging, automotive, and construction industries.

Expansion in Specialty Polymers: The increasing need for high-performance materials is leading to a surge in demand for initiators tailored for specialty polymers used in electronics and medical devices.

Market Analysis

The polymerization initiator market is influenced by various factors:

Drivers: The growing demand for lightweight materials in automotive and aerospace industries and the rising adoption of bio-based polymers.

Restraints: Regulatory challenges and environmental concerns related to conventional initiators.

Opportunities: Development of non-toxic, biodegradable initiators and increasing applications in niche sectors such as bioplastics and nanocomposites.

Market Segmentation

By Type:

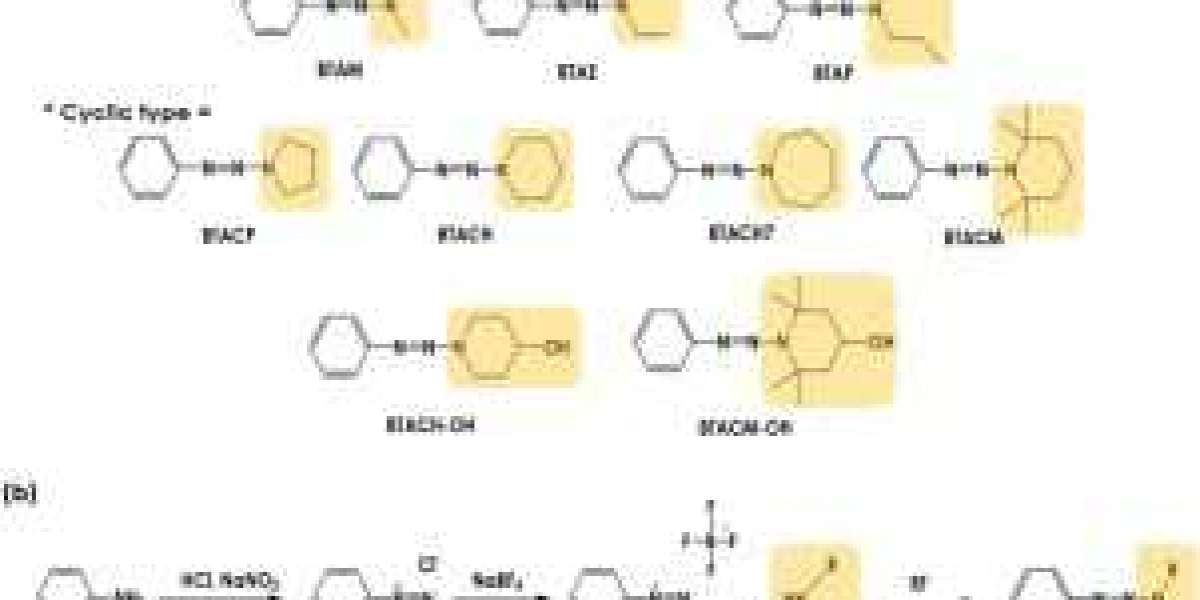

Persulfates: Widely used in radical polymerization due to their strong oxidizing properties.

Peroxides: Dominant in high-temperature polymerization processes.

Aliphatic AZO Compounds: Gaining traction for their controlled release mechanisms.

Others: Include novel initiators catering to specific industrial needs.

By Active Species:

Free Radical: Most commonly used in the production of polyethylene and polypropylene.

Anionic: Preferred for high-performance and specialty polymers.

Cationic: Found in niche applications such as the production of epoxy resins.

By Application:

Polyethylene: Dominates due to its use in packaging and consumer goods.

Polypropylene: Popular in automotive and textiles.

Polyvinyl Chloride (PVC): Increasingly used in construction.

Polystyrene: Growing demand in electronics and insulation.

Acrylonitrile Butadiene Styrene (A.B.S.): Used in durable consumer goods and engineering applications.

Others: Specialty polymers for medical and aerospace industries.

Market Growth

The market is set for steady growth due to the expansion of end-use industries and advancements in polymer technologies. Market growth is driven by increased demand for lightweight and durable materials, particularly in packaging and automotive sectors. Government initiatives promoting sustainable materials and investments in RD are expected to further accelerate growth.

Recent Developments and Challenges in the Market

Recent Developments:

Leading players are launching eco-friendly and high-performance initiators to meet regulatory standards and consumer preferences.

Strategic collaborations and acquisitions are enhancing market penetration and product diversification.

Emerging technologies, such as plasma-initiated polymerization, are gaining attention for their potential to revolutionize the industry.

Challenges:

Stringent environmental regulations pose challenges to the production and disposal of traditional polymerization initiators.

Volatility in raw material prices affects cost stability and profitability.

Educating end-users about the benefits of advanced initiators remains crucial for market adoption.

Key Players in the Market

Prominent companies shaping the global polymerization initiator market include:

Akzo Nobel N.V.

BASF SE

Arkema S.A.

United Initiators GmbH

ADEKA Corporation

Celanese Corporation

LANXESS AG

These players focus on innovation, sustainability, and strategic alliances to maintain their market positions and expand their product offerings.

Upcoming Challenges in Market

Balancing cost-efficiency with sustainability remains a significant challenge for manufacturers.

The transition to bio-based polymerization initiators demands substantial investments in RD and production infrastructure.

Global supply chain disruptions and geopolitical factors can impact the availability of raw materials and finished products.