When it comes to plastic manufacturing, choosing the right molding technique can significantly impact both the production cost and the final product’s quality. Two of the most commonly used methods in the plastics industry are blow molding and injection molding. While each has its unique advantages, the primary concern for manufacturers often comes down to one question: Which one saves more money—blow mold vs injection mold?

This comprehensive guide delves into the cost factors, applications, production scale, tooling expenses, and long-term value of blow mold vs injection mold. Whether you're a product developer, business owner, or engineer, understanding these differences can help you make smarter decisions that align with your budget and production goals.

Understanding the Basics of Blow Mold vs Injection Mold

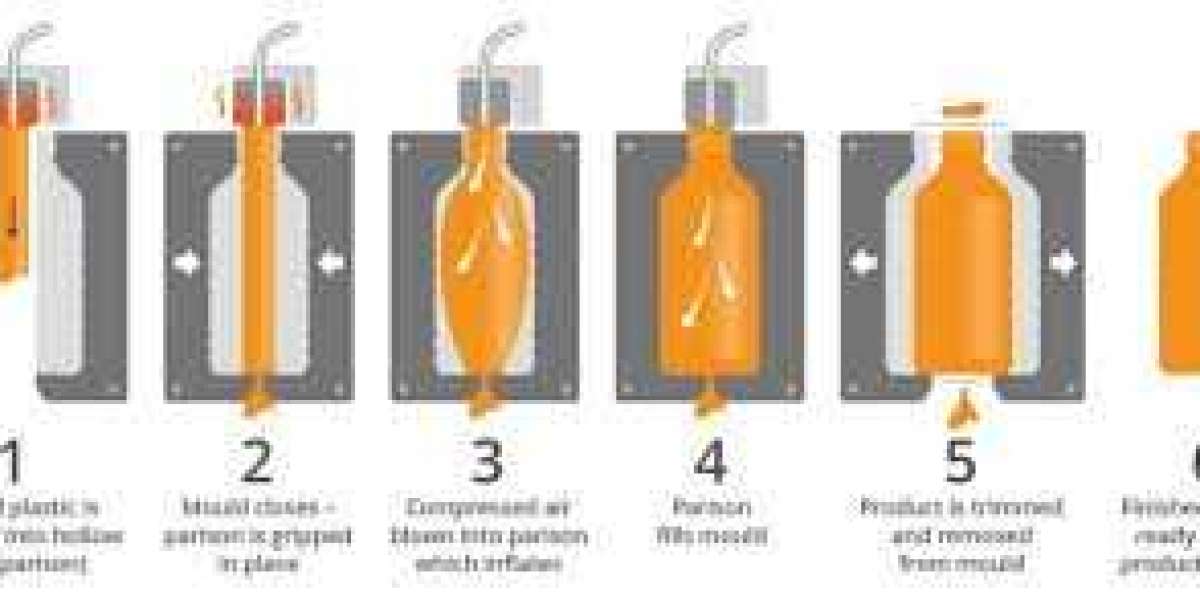

Blow molding is a manufacturing process used to create hollow plastic parts such as bottles, containers, and tanks. It involves melting plastic and forming it into a parison or preform, which is then inflated within a mold to take its shape. This method is excellent for high-volume production of uniform, lightweight items with thin walls. The key advantage lies in its efficiency in producing hollow parts with minimal material waste.

Injection molding, on the other hand, is used to manufacture solid plastic parts by injecting molten plastic into a mold cavity under high pressure. After the plastic cools and solidifies, the mold opens to release the finished part. This process is ideal for complex, precision-engineered components. From automotive parts to consumer electronics housings, injection molding is known for its ability to deliver high detail and structural strength.

Tooling Costs: Initial Investment Comparison

When evaluating blow mold vs injection mold from a cost perspective, tooling expenses play a major role. Blow molding typically requires simpler molds and lower tooling investment. Since it’s designed for creating hollow objects, the molds are generally one-sided or less intricate. This simplicity leads to quicker mold creation and lower upfront costs, making blow molding attractive for startups or companies looking to enter the market with minimal financial risk.

In contrast, injection molding requires highly engineered molds capable of withstanding significant pressure. These molds must be precision-machined with complex geometries and often include moving components, cooling systems, and multiple cavities. As a result, the initial cost for an injection mold can be significantly higher—often tens of thousands of dollars. However, these molds are extremely durable and can be used to produce millions of parts with consistent accuracy, which may offset the upfront investment over time.

Production Volume and Cycle Time

One of the most critical factors in determining cost efficiency in blow mold vs injection mold is production volume. Blow molding is ideal for large-scale production runs of hollow items like beverage bottles and fuel tanks. The cycle time in blow molding is relatively fast for single-cavity molds, and it can be scaled up using multiple cavities. Because of the lower pressure involved, the equipment experiences less wear and tear, potentially lowering maintenance costs.

Injection molding, however, excels in high-speed, high-volume production of small and intricate parts. Despite having a higher cycle time per part compared to blow molding, injection molding machines can be equipped with multi-cavity molds to increase throughput. Additionally, automation options in injection molding further enhance production speed, consistency, and cost savings when manufacturing tens of thousands or even millions of parts.

Material Usage and Waste Reduction

In the debate of blow mold vs injection mold, material efficiency is another key point of consideration. Blow molding uses less plastic for creating hollow parts, which naturally leads to lower raw material costs per unit. Because the walls of blow molded products are thin and uniform, manufacturers can produce lightweight parts without compromising functionality. Moreover, blow molding typically generates less scrap material, especially when using extrusion blow molding techniques.

Injection molding, while offering precise material control, often involves more material usage due to sprues, runners, and gates—elements that are essential for channeling the plastic into the mold. Unless these excess materials are recycled, they contribute to higher waste and cost. However, advancements in hot-runner systems and post-processing recycling can help mitigate this issue, making injection molding more material-efficient than it used to be.

Long-Term Cost Efficiency and Product Lifespan

The long-term cost efficiency of blow mold vs injection mold depends on your specific product requirements and production lifecycle. Blow molding typically results in lower per-unit costs for hollow products at scale, particularly when design complexity is low. For industries like packaging, pharmaceuticals, and automotive fluid containers, blow molding delivers a cost-effective solution with sufficient durability and minimal ongoing maintenance.

Injection molding offers exceptional value over long production runs, especially for products that require tight tolerances, detailed features, and high structural integrity. While the upfront mold investment is higher, the longevity of the mold and the consistent quality of parts contribute to lower costs per unit over time. For manufacturers in electronics, medical devices, and precision tools, injection molding provides a scalable, cost-justifiable solution that aligns with long-term profitability goals.

Conclusion

There is no one-size-fits-all answer in the blow mold vs injection mold debate. The cost-effectiveness of each method depends heavily on the part design, production volume, material, and the level of detail required. If you are producing simple, hollow parts in high volumes, blow molding typically offers a lower cost per unit and reduced tooling expenses. It’s a preferred choice for packaging and lightweight containers where structural strength is secondary.